DIGITAL TEXTILE PRINTING - THE LATEST PRINTHEAD DEVELOPMENTS NOW DRIVING SPEED AND STABILITY

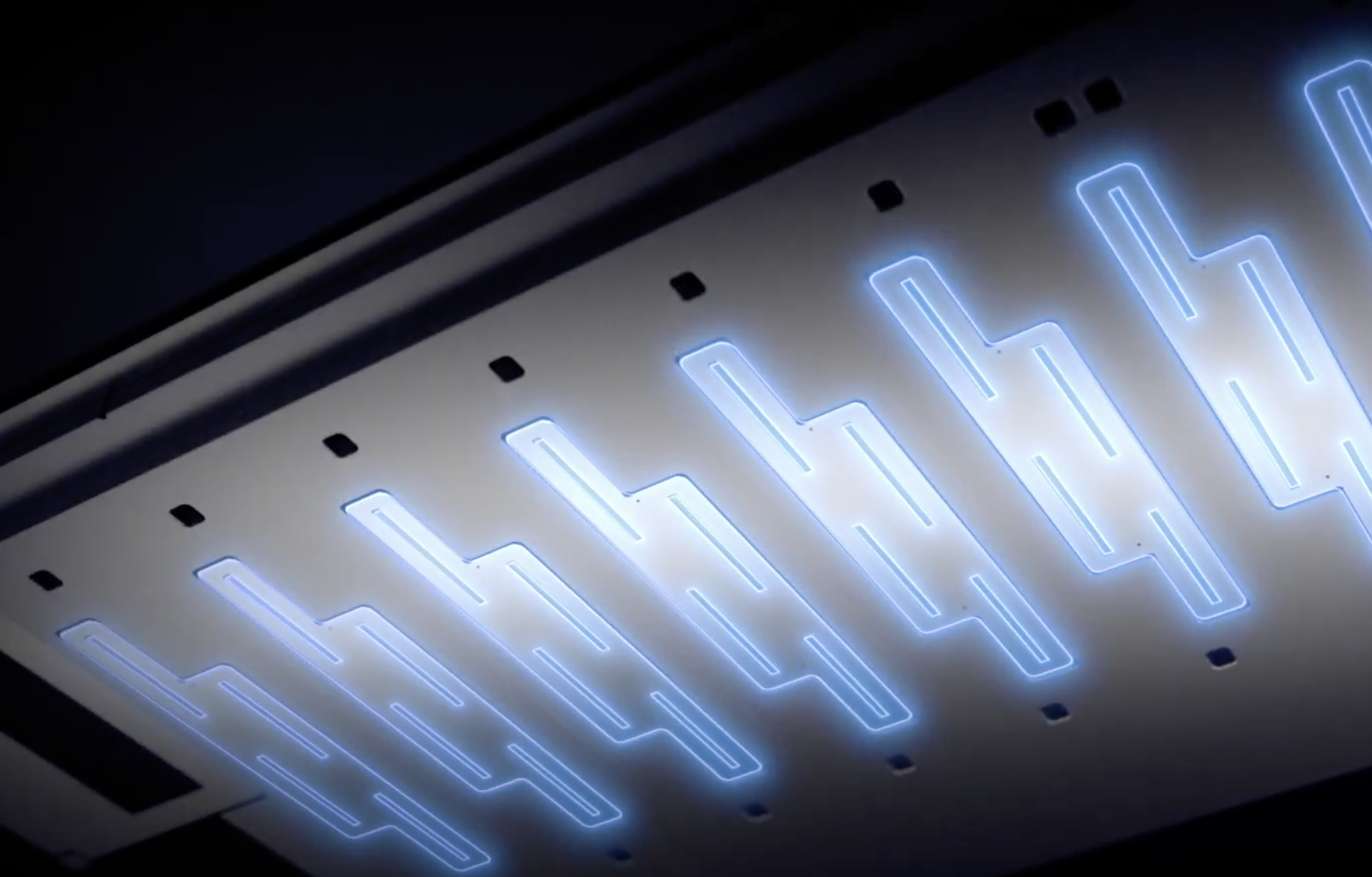

“Behind the irreversible rise in the application of digital textile printing we have seen marked progress in ink formulation, and the evolution of smart, intelligent machinery and intuitive software taking place across the sector. None of which would have been possible without the phenomenal strides and innovations made with printhead and circuit board technology.” Image Credit EPSON

Digital Textile Printhead and Circuit Board Developments — Innovations driving change

Printed perfection starts at the Printhead, a vital component, without which we wouldn’t have a digital printing industry. The global inkjet print heads market was valued at US$ 2.01 billion in 2020, and is expected to reach US$ 2.63 billion by the end of 2026, growing at a CAGR of 3.9% during 2021-2026 (Source: The Market Reports)

Behind the irreversible rise in the application of digital textile printing we have seen marked progress in ink formulation, and the evolution of smart, intelligent machinery and intuitive software taking place across the sector. None of which would have been possible without the phenomenal strides and innovations made with printhead and circuit board technology.

Starting with Ricoh whose Ricoh Th5241 is the first printhead to use a thin film piezo actuator. By using MEMS technology – Ricoh's unique design means the Th5241 is a compact printhead with 320 x 4 rows of 1,280 nozzles. In addition, high-definition printing of up to 1200 dpi can be achieved by jetting fine droplets. Also, ink paths for each nozzle row are isolated, enabling a single printhead to jet up to four ink colours. The printhead has compatibility with all ink types including UV, solvent, and aqueous and can be used for various industrial applications such as sign graphics, textiles and labels.

<<Learn More >>

Kyocera has been at the forefront of the digital revolution in commercial printing globally since 2007, when it first applied its proprietary fine ceramic technology to create ultra-high-speed piezo actuators for its world-record-setting KJ4 series inkjet printheads. The new KJ4 EX series builds on this legacy with a large, integrated piezo actuator and streamlined structure. By increasing the volume of each drop of ink ejected from the printheads and enhancing droplet-ejection consistency, the new series allows high-resolution printing on a wider variety of media. At the same time, the printheads durability is enhanced by improving its structural strength and rigidity.

<<Learn More >>

Xaar Plc – with its Xaar 2002, has a ‘highly advanced printhead’ designed to deliver exceptional 720 dpi print resolution quality and performance across a range of applications including ceramics, textiles, glass, packaging and label applications. The new Xaar 2002 has been developed specifically to provide fast and easy integration and is ready to use straight out of the box. Using drop in printhead alignment, mechanical tolerance improvements allow the printheads to be dropped into the print bar easier, making set-up times faster, and machine builds quicker. Print speed is greatly enhanced with the Xaar 2002, enabling lines to be run faster. By using the full capability of the printhead, much higher firing frequencies of up to 36 kHz are now possible, delivering significantly increased printing speeds of up to 75 metres per minute at 720dpi.

<<Learn More >>

The new FUJIFILM Dimatix’s printhead, the DIMATIX Samba G5L leverages state-of-art silicon micro electro-mechanical systems manufacturing (SI-MEMS), the DIMATIX Samba G5L printhead has a unique parallelogram design on the nozzle plate to offer simplified printhead stitching — enabling integration in production environments. The DIMATIX Samba G5L also offers a 30%-45% larger drop size (3.5 – 13pL), providing higher in coverage at production speeds at 1,200×1,200 or 1,200×600 dpi printing to produce colour rich prints. Optimized for single-pass, the DIMATIX Samba G5L offers a fast priming, higher standoff capability (up to 4 mm, without air assist and up to 5mm with air assist), and reduced maintenance cycles from multi-level ink recirculation, to limit downtime.

<<Learn More >>

The New Epson PrecisionCore Micro TFP Printhead offers precise temperature control, which is monitored by four temperature sensors, ensuring colour is consistent from edge to edge and top to bottom. Three independent heating stations (preheat / platen heat / post-cure heat) ensure colour uniformity and adept media handling. The long-life PrecisionCore Micro TFP printhead means accurate and repeatable colour from first print to the very last. As Piezo printheads are not subjected to thermal degradations, droplet placement and dot sizes remain consistent throughout the life of the printhead, and when the printhead does need replacing, it can be carried out by the operator boosting uptime and productivity

<<Learn More >>

Global Inkjet Systems’ flexible drive electronics for the Seiko RC1536 Printhead. Developed through working in close collaboration with Seiko following high customer demand, GIS developed the HMB-SII-1536 head manager board to drive the performance of this high-productivity ink recirculation printhead to its fullest potential. The Seiko RC1536 printhead can accept a wide range of viscosities and is compatible with oil, UV, solvent and aqueous based fluids – ideal for a wide range of applications, including high laydown coating & varnish, additive manufacturing, ceramics, textiles and more. Featuring a wide print-width (108mm), the printhead also achieves up to 10 levels of greyscale with a drop range size between 13pl to 225pl.

<<Learn More >>

Meteor Inkjet including scalable electronics and comprehensive software for Epson’s new S1600 and S800 PrecisionCore printheads. Epson PrecisionCore printheads embody technology that enables outstanding image quality, productivity, durability and printhead scalability. The S1600 and S800 are built with the same thin film piezo building blocks as the S3200 and have been developed in response to customer requests for smaller printheads. With its compact form factor, the S1600 is ideally suited for carriage mounting in scanning applications, while the fine nozzle pitch and small surface area of the S800 is perfect in direct-to-shape applications. Coupled with Meteor’s unique capability to combine printhead types from the same or different printhead families, OEMs can reduce the time and risk associated with the design and delivery of complex industrial inkjet systems. Moreover, Meteor’s Drop Watcher is an essential tool to accelerate time to market for new inkjet applications